HK Group is one of the earliest companies that made effort in graphene research and development. Mass production of graphene is a hotspot of study in today's world. Most companies and research institutions use unclean or even polluting methods to make graphene, discharging a lot of sulfuric acid, causing serious environmental pollution. Other methods are costly. HK Group invested in the UCLA graphene lab and developed a unique method that is completely pollution-free and at low cost.

Besides the UCLA - HK Graphene Research Center, HK Group also established the Lianyungang Graphene Research and Development Center. The Center is capable of producing single layer graohene in mass quantity in an environmentally friengly way and at low cost. The entire production process needs no sulfuric acid and causes no pollution. Inspection report shows final products of world class quality.

HK Group owns the world's most advanced lithium titanate battery cells, modules and packs. It has the world's leading battery experts. First generation of HK eBus using the LTO batteries has been tested successfully for two years, meeting all the design requirements.

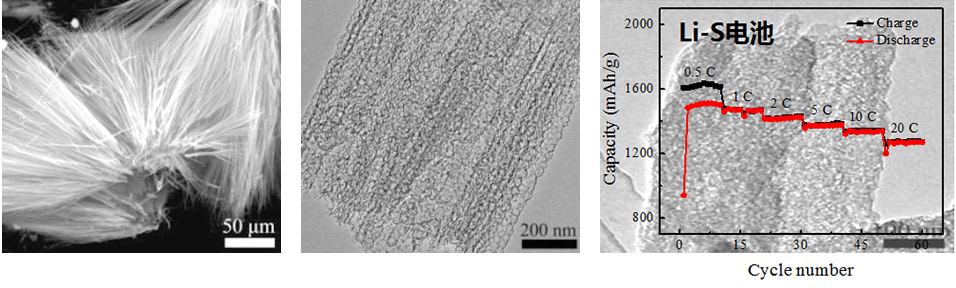

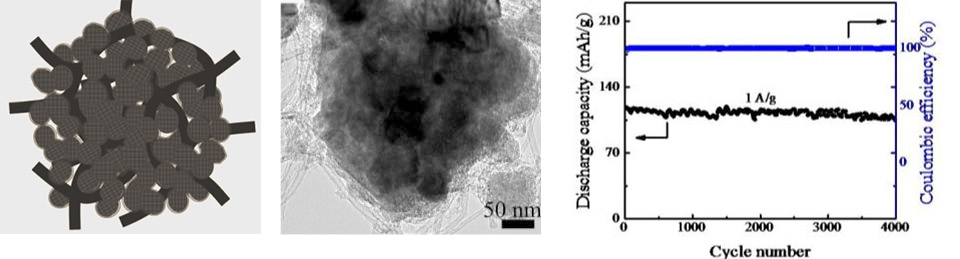

HK Group and world's largest and most advanced lithium titanate battery manufacturer conducted exclusive cooperation,combining strength of the two sides in graphene and battery technology and successfully developed graphene enhanced LTO battery. At the same time, HK Group is developing graphene lithium sulfur batteries. Conventional lithium ion battery energy density is about 120 watt-hours per kilogram. Better clean energy electric vehicles will require better batteries of longer life and higher energy density.

Therefore, development of high energy density power/energy storage batteries has become the pressing need of the market. At present, HK Group is working with UCLA for preproduction testing.

US patents pending for graphene

Graphene production line in China

Graphene is an important part of HK clean energy strategy

Cycle life > 100,000;

Fully charged in minutes/seconds;

50-100 times the power density of conventional lithium batteries;

5-10 times the energy density of conventional lithium batteries;

High DOD efficiency (98%);

Working under -50 ℃ ~ + 70 ℃;

Non-explosive, nonflammable.

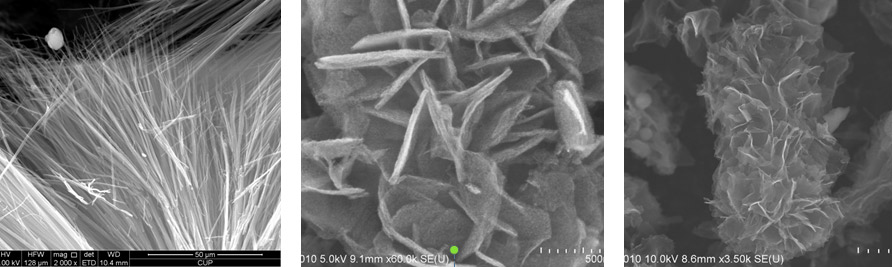

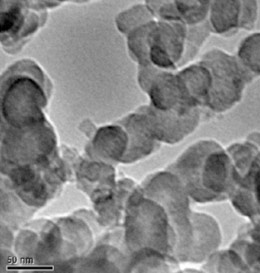

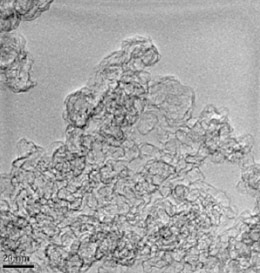

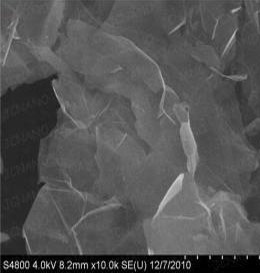

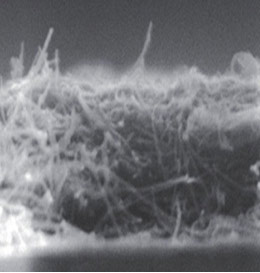

Porous graphene fiber, films and three-dimensional structured powders.

High specific surface area (1500 m2 / g), indicating single layer graphene.

Environment friendly production process does not discharge waste gas, acid or liquid.

Fluidized bed production technology enables mass production.

Porous graphene with big specific surface area (2140 m2 / g). Hole size can be customizable and catalyst can be recycled.

Applicable in lithium batteries, capacitors and for energy storage purposes.

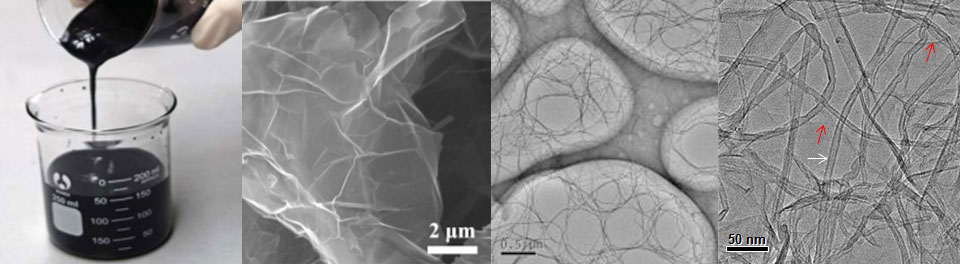

Better conductivity

Easier conductive network

Less addition amount

Graphene products less than 10 layers, carbon nanotubes easily form network;

Production process is pollution free. No discharge of waste gas or waste acid. Environment friendly;

Production cost is low.

Super fast charging and discharging;

High capacity close to the theoretical value of lithium titanate;

Excellent cycle life.